Lessons I Learned From Info About How To Build A Pcb

Etch the inner layers or core to remove copper.

How to build a pcb. Advanced circuits inc 2004 17 copper foil the copper. By working on circuits, students will learn how to use altium to. Printing the copper for the interior layer.

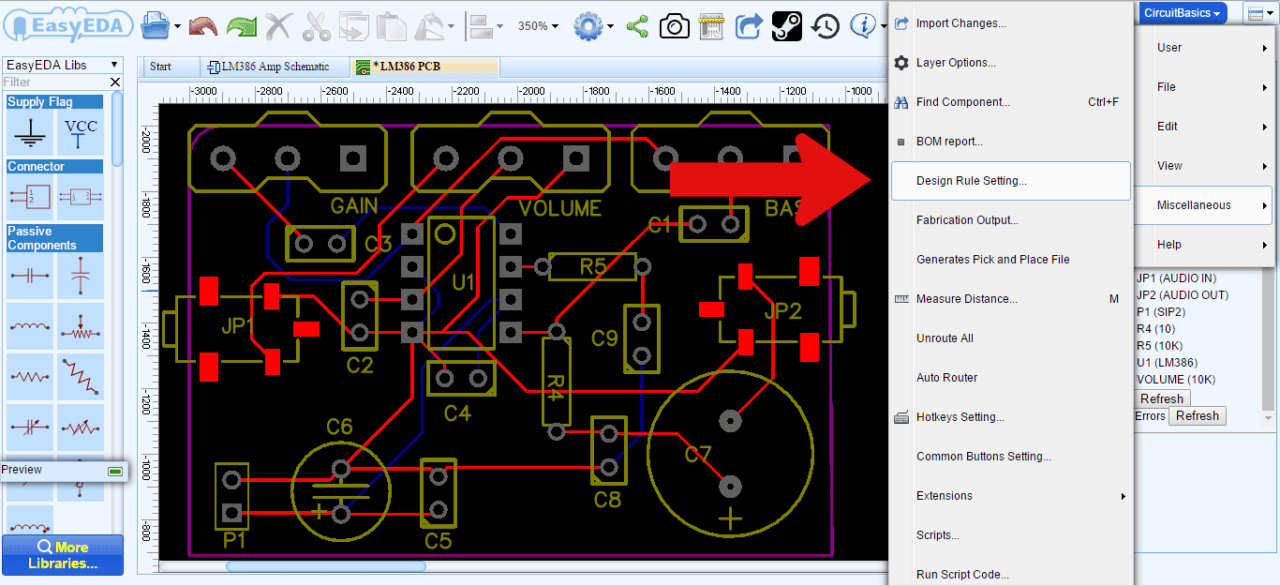

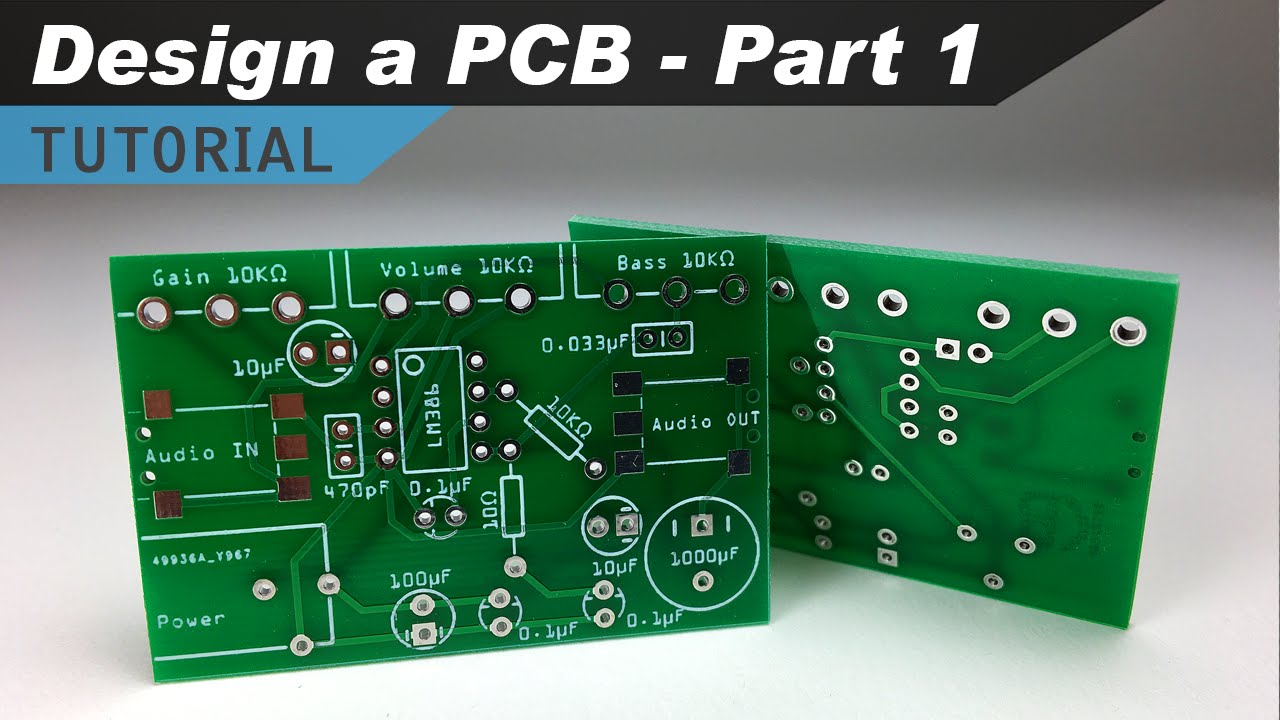

This course is designed to help students learn altium pcb design through the process of building circuits. I’d also say check it in 3d to ensure it’s. Up to 10% cash back the pcb design learning by building circuits course is aimed at giving users a strong foundation in the basics of pcb design and how to use altium software.

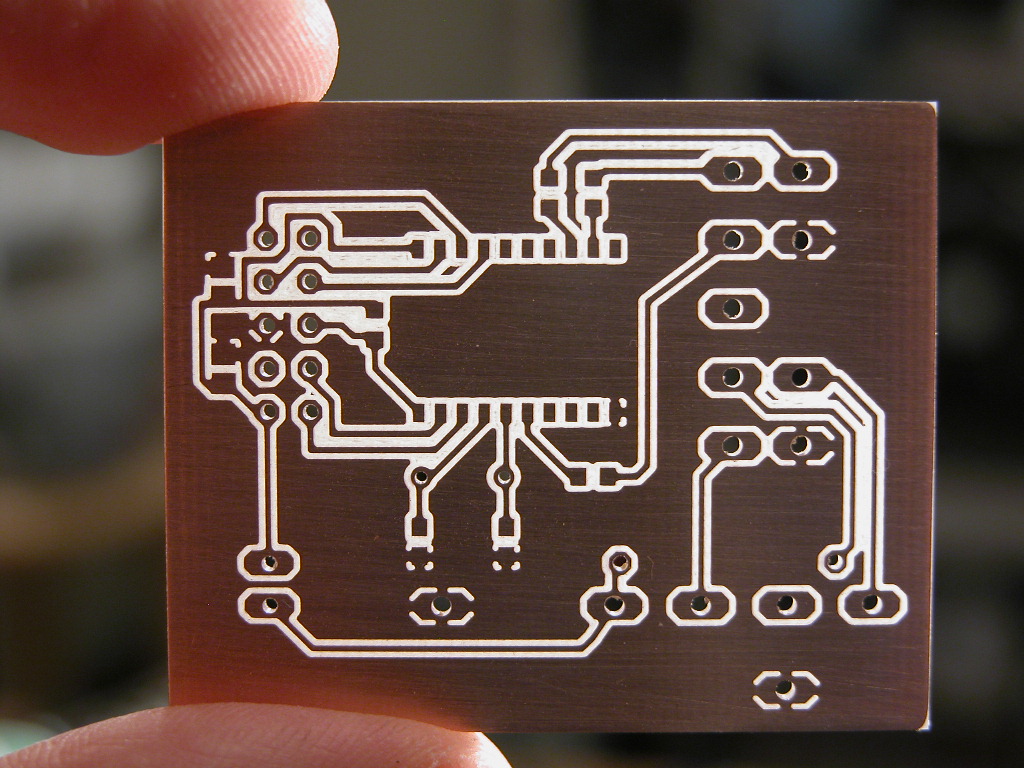

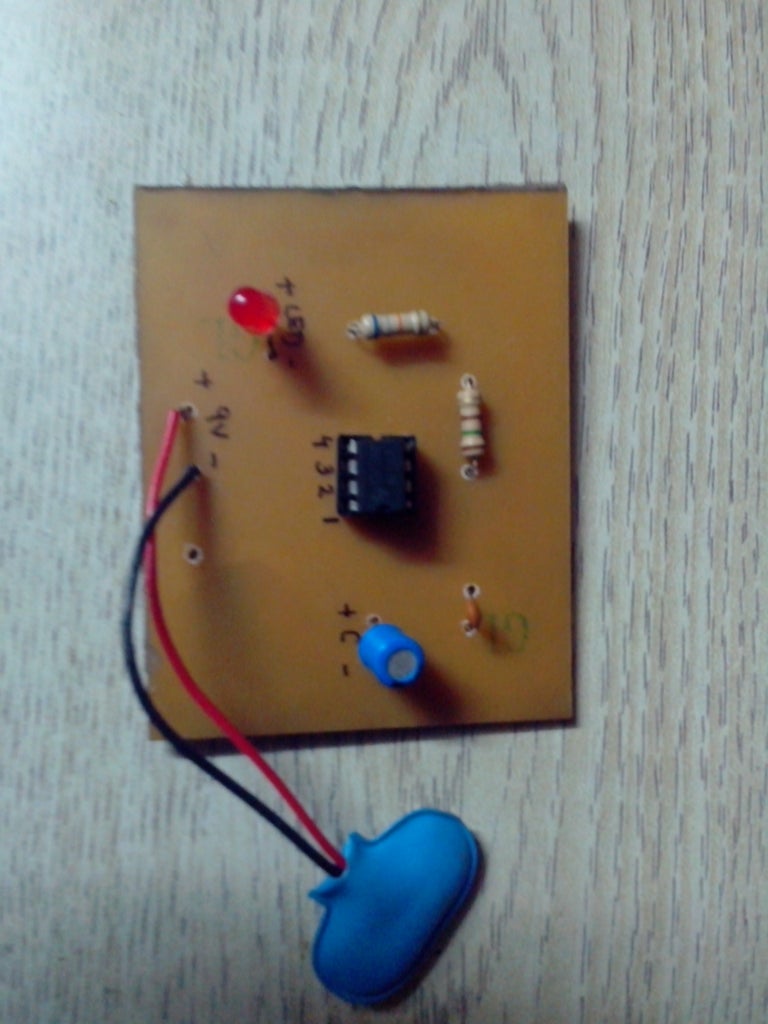

First, scrub the copper clad via a scrubber to eliminate dust and other surface deposits. In surface mount technology, a standard via example is the through. Method of iron on glossy paper the circuit on pcb by hand machining laser edge etching.

Components and layers can then be added to engineer and build a. Next we just add the annotations to the board. Foil prepreg core prepreg foil.

Next, using the above transmitter circuit diagram, make a block diagram. Different ideas to make own pcb at home: There are lot of paid and free softwares available for this purpose,.

Ad high quality pcb fabrication & assembly services. Obedience training is one of the most rewarding things you can ever offer yourself and your dog. A printed circuit board, commonly called a “pcb,” is a (usually) rigid board printed with electrical circuitry called traces.

Basic commands like sit, stand, no, and stop can help you. Ad pcb and pcba online quote, quick turn pcb and pcb assembly, promotion & discount prices! It is good to use to set items.

A pcb milling machine (referred to as a 'pcb prototyper') operates in a. Currently, the process of creating a ”found object” can be simplified as follows: Designed components to be produced are nested on a sheet of material.

Drag the connector into place. Usually, pcb houses will manufacture in large quantities (to reduce the cost) and if you are. Surface mount technology involves the use of solder paste.

Applying solder and solder paste during smt pcb assembly. Then go to the pcb layout and import the components. Using pcb houses is a good idea if you are developing commercial products.