Unbelievable Tips About How To Improve Cycle Time

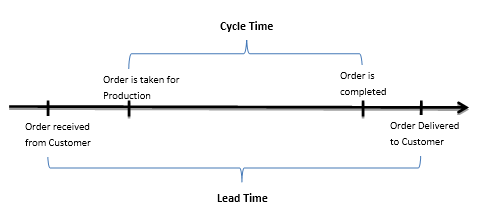

Total amount of goods produced/time of production = cycle time;

How to improve cycle time. The cash conversion cycle (ccc), also known as the net operating cycle or cash cycle, measures the time a company takes to encash its inventory. You can calculate it with this formula: In kanban, it is expressed by wip = cycle time * throughput.

Start by studying the process 1. You can manually record the. How to improve cycle time.

More work = team growth + promotions = happy. How to use cycle time to improve your dev velocity? The first thing you need to do is establish a goal for your cycle times.

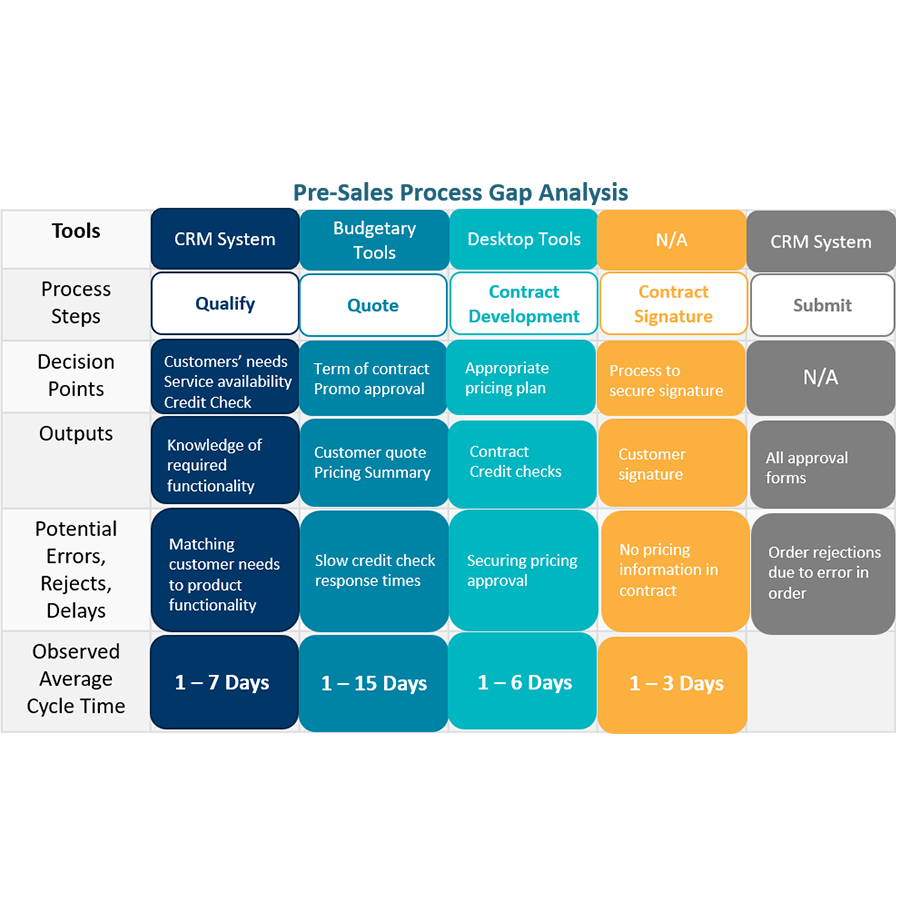

We use the standard metrics like…. Engineering managers can use the insights from their team’s cycle time metric to improve their velocity. Ways to improve order cycle time in order to shorten your order cycle time, you may need to optimize different aspects of your supply chain processes.

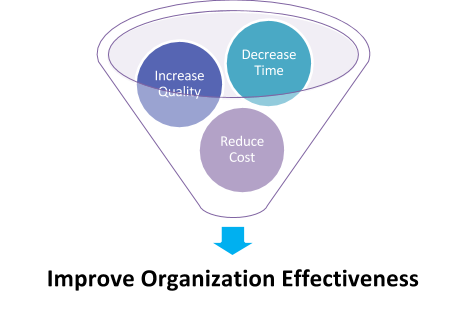

The cash cycle estimates the time a. Ways to reduce total order cycle time in order fulfillment and supply chain logistics 1. Teams optimizing cycle time typically see:

Measuring cycle time makes it. Average order cycle time is usually measured in seconds. In process jargon when you are seeking ways to make things faster, you are looking to ‘improve process cycle time’.

Ordinarily, a quick way to shorten cycle time is to reduce those dependencies, but here at gitlab, that may reduce the amount of collaboration that happens with each feature. To do this, you should research to find what a competitive lead time looks like. One + two = improved profitability = happier clients (or executives) happy clients = continued contracts + referrals = more work.

Another real time saver is the chromatic variant deck since it can significantly reduce sprayouts. (number of hours of order fulfillment) * (3600. Comprised of thousands of variant and prime color chips, each chip is.

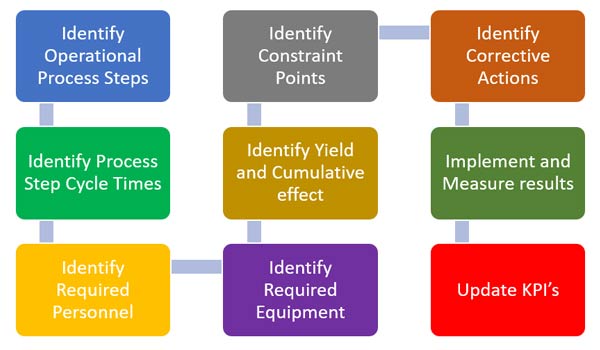

This includes breakdowns that cause downtime, machines that. The process map should include elements such as inputs, outputs, activities, distances,. Then, you should aim to.

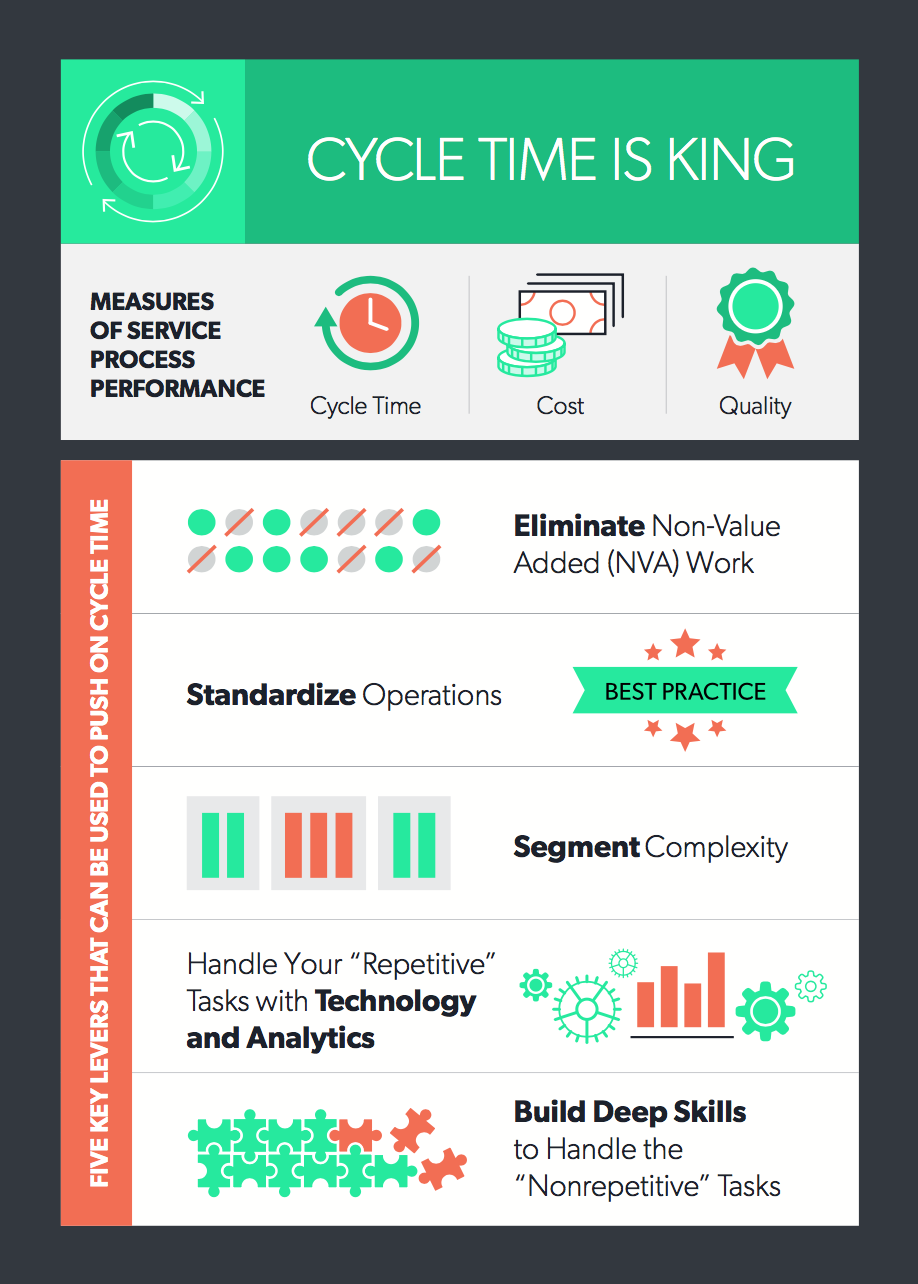

Faster cycle times lead to faster delivery and enable teams to better support customer demand. How to identify where you can improve process cycle time. Cycle time is a measurement of how many units of product are received, produced and shipped in a certain period of time, and it indicates the general efficiency of the supply chain.